Smart factory

RFID production information tracking system

RFID production information tracking system. It will use advanced RFID technology and rely on network technology and database technology to realize information fusion, query, and monitoring, and provide reasonable production information sources and inventory control for each product during each production stage and the process of distribution to the final consumption field. decision making.

The system provides data basis for the establishment of intelligent production lines, realizes intelligent identification of product models and parts models to complete model matching, provides important guarantees for optimizing production processes, and at the same time provides guarantees for the establishment of a sound production line product backtracking and product recall mechanism.

System components: RFID reader, RFID tag, MES information system, server.

Recommendations for the use of hardware products:

860~960MHz UHF Mid-range All-in-One Reader Model: C216023

UHF 860~960 Gen 2 Desktop RFID Reader Model: C236028

Anti-metal RFID tag with super high frequency band magnet Model: C116036

UHF Anti-metal RFID Tag Model: C116037

UHF Small Anti-metal RFID Tag Model: C116039

Among them, the RFID part is provided by Changzhou Gaote, which can be docked with the customer's MES information system, or provide basic development kits for independent development by customers.

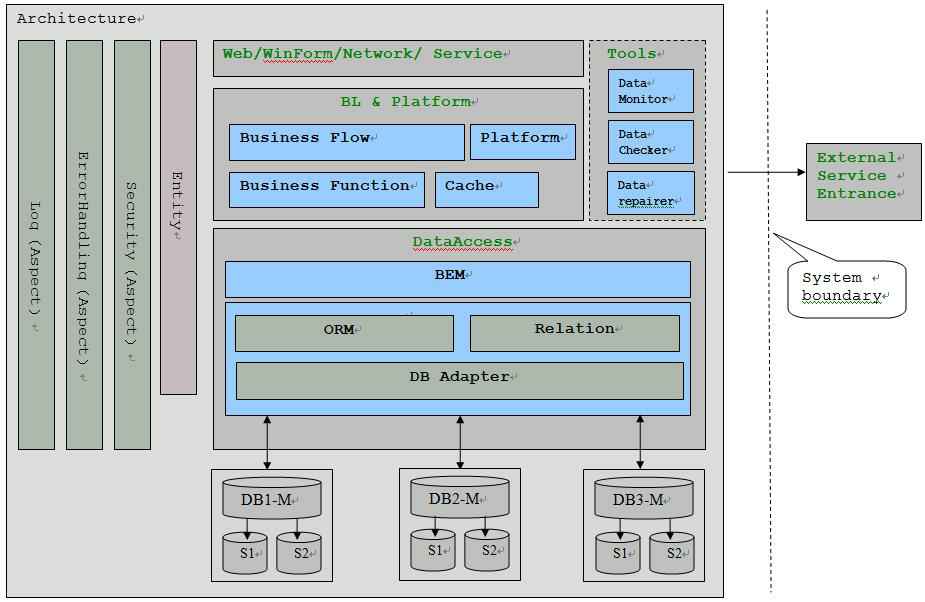

RFID software architecture diagram:

Production process management case:

The RFID tag is fixed on the pallet, the PLC receives the production information from the MES system, and the system gives the reader instructions to write the information into the RFID tag, and displays the written content on the display.

(Case scene picture 1)

(案例现场图片2)

长沙立德信息技术应用有限公司是RFID物联网行业知名企业,公司拥有全套的RFID技术,提供各类RFID阅读器,RFID电子标签,RFID系统,竭诚为全国客户提供相关的物联网产品及服务。欢迎咨询与合作。

Scan code and wechat

Scan code and wechat